GWL-2300 Global Wheel-Lok™ Restraint

Benefits

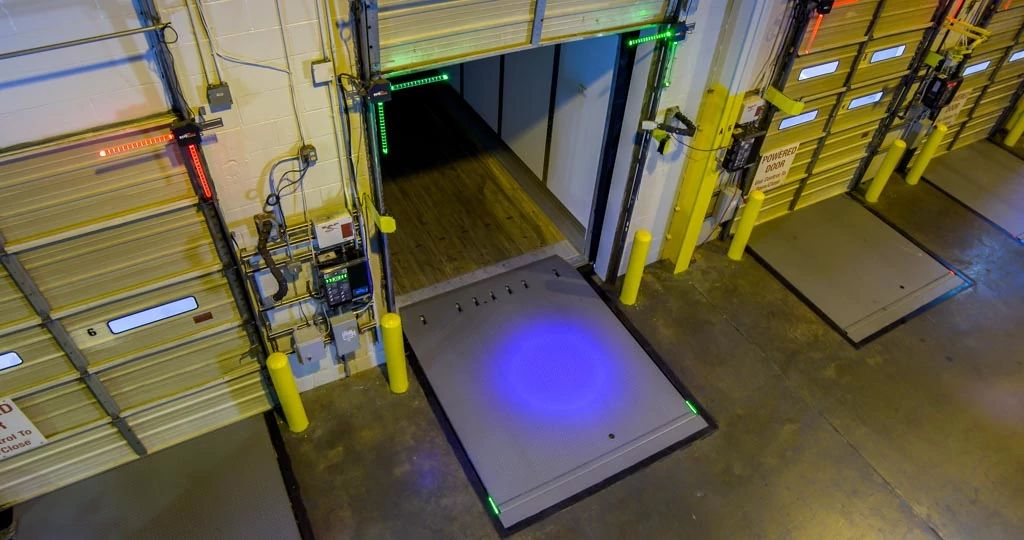

Designed and Installed for Productivity

Safety at the Loading Dock

Communication and Control

Smart, Connected Capabilities

Industry Leading Warranty

- Automatically Secure Widest Variety of Trailers – Superior-strength high 20” steel locking arm helps automatically secure trailers with a 30-44” tire diameter. No external power as trailer contacts trigger device and energy of the trailer pivots the barrier locking arm into position.

- Wide Engagement Range – Engagement range extends from 43” to 158’’ from the back of the trailer to the front of the rear-most tire to help mitigate fulcrum point on the trailer.

- On-Center Trailer Positioning – Two wheel guides ensure on-center trailer positioning to enhance dock sealing effectiveness. Dock seals effectively minimize gaps around the trailer to help achieve maximum environmental control for lower energy cost and product quality support.

- Remote Power Unit – Hydraulic fluid mounted in alternative location, away from harsh loading dock environment. Biodegradable Fluid option is environmentally friendly and outperforms traditional industrial-grade fluid.

- Integrity of Installation – Completed dock survey required for each dock position to help ensure safe and proper application of all Dok-Loks. Critical to the safety of material handlers and equipment utilizing the equipment, the surveys are reviewed by expert Applications team if outside of standard dock configuration.

- Pull-Out Force Benchmarks – Rite-Hite was the first loading dock equipment manufacturer to establish pull-out force benchmarks based on years of research and development. Followed today by many other manufacturers, GWL-2300 is installed with mounting force in excess of 100,000 lbs. and 32,000 lbs. of pull-out force, doubling what tractors can achieve when in first gear.

- Withstand Harsh Loading Dock Environment – Reliable, low maintenance structural and formed steel design performs in all weather conditions. All surface-mounted wheel-based restraints are zinc-metalized and painted for corrosion resistance at the loading dock.

- Liftgate Stored to Disengage – Optional safety sensor requires liftgate to be stored before the restraint “unlock” button is operable to maintain safe sequence of operation. Sequence helps prevent trailer from pulling away with liftgate dragging on the drive approach, damaging trailer and restraint.

- Communication and Control – Dok-Lok® Style Light Communication communicates via interior lights when trailer is properly engaged, thus safe for material handlers to enter.

- Help Prevent Trailer Separation Accidents – GWL-2300 helps to prevent early departure and trailer creep, while a trailer stand can assist with landing gear collapse and trailer upending.

- Certified to meet and exceed ANSI MH30.3 performance testing standards.

Rite-Hite Communication and Control allows facilities to:

- Integrate additional/future equipment and interlocked sequence of operations with Dok-Lok® Style Light Communication System.

- Incorporate line of sight light communication system status with Corner-Vu™ and Leveler-Vu™.

- Extend Blue Light Policy to help prevent 80,000 annual forklift-pedestrian accidents by extending reaction time with Pedestrian-Vu™.

- Help prevent 2nd leading cause of backover fatalities in the United States with Approach-Vu™, which utilizes a light and horn system to present a clear visual and audible warning to pedestrians in the drive approach when a backing vehicle is detected.

- Verify Dok-Lok engagement and trailer stand presence via outside camera and inside monitor with Lok-Vu™, reducing the amount of processes on the dangerous drive approach.

- Integrate multiple loading dock control components at each dock position for a total dock safety system with Dok-Commander® Combined Controls.

All components are available as standalone or incorporated with Dok-Lok Style Light Communication System. The Dok-Lok Style Light Communication System offers more flexibility, facilitating the greatest long-term yield per dock position. The system allows facilities to address their most urgent safety needs first but reserving the opportunity to integrate vehicle restraints and other safety solutions at a fraction of the cost compared to standalone equipment purchases.

Loading Dock Productivity Analytics

- Monitor real-time loading dock status. Optional Dok-Lok Dock Timer digitally displays total engagement time at each position to help dock attendants prioritize loads and avoid costly detention and demurrage charges.

- Leverage loading dock analytics with current and historical Dok-Lok efficiency and utilization data to identify areas of operational improvement through robust reporting and intuitive dashboards.

- Receive trending productivity alerts and review correct actions / next steps.

- Study and understand safety challenges, frequency trends and root cause with diagnostic analytics to proactively influence employee behavior.

- Interactive Safety Assessment Tool helps place priority on specific safety events.

- 12-Month Limited Money-Back Guarantee of Customer Satisfaction

- Standard Warranty includes 1 year parts / 1 year labor

- Rite-Hite® Extended Warranty includes 2 year parts / 2 year labor and smart, connected capabilities

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.