Dok-Commander® Combined Controls

Benefits

Designed and Installed for Productivity

Safety at the Loading Dock

Communication and Control

Connected Capabilities

Industry Leading Warranty

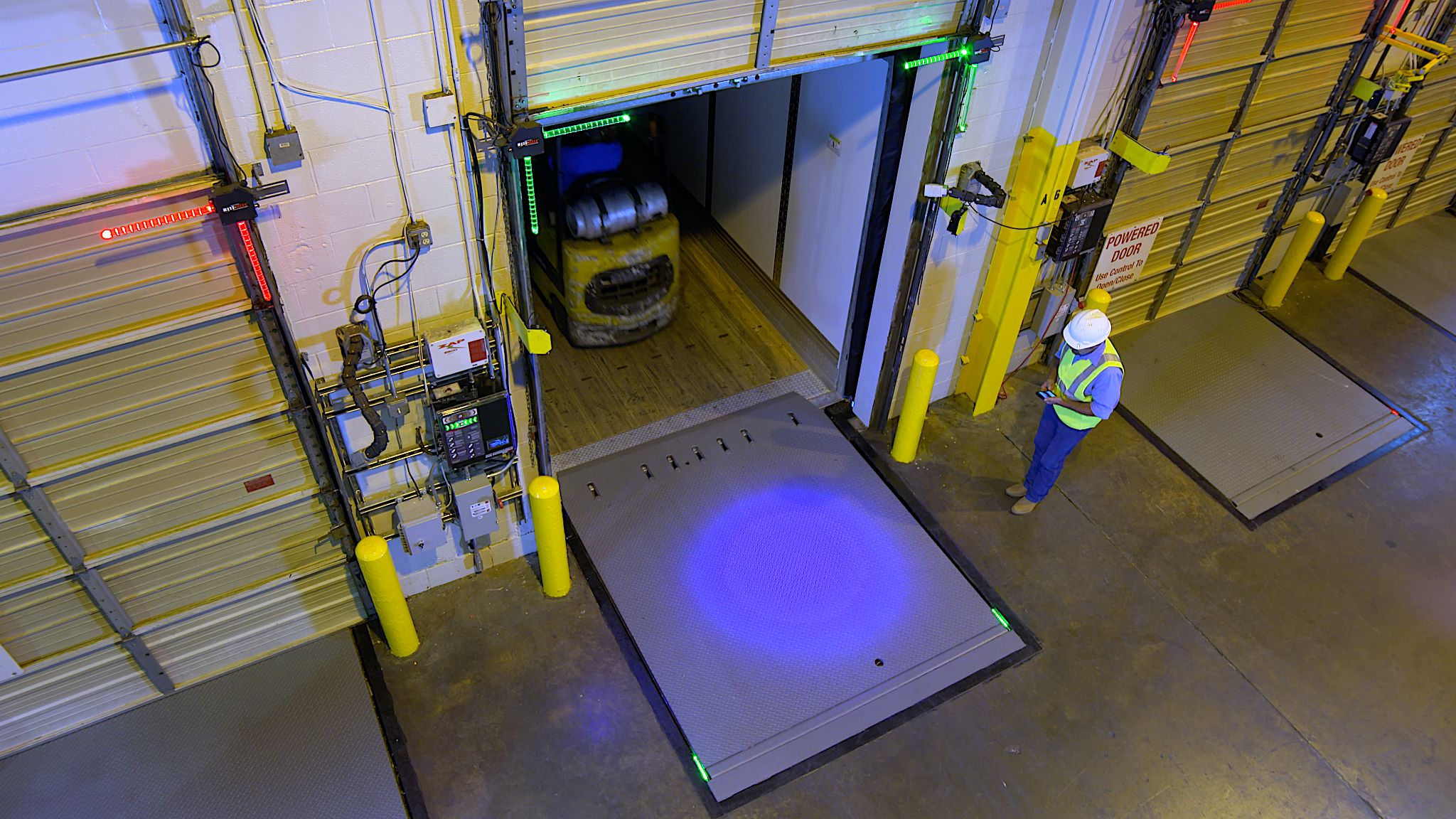

- One Simple, Centralized Control Panel – Dok-Commander® Combination Control Panel integrates multiple pieces of loading dock equipment, such as: vehicle restraints, dock levelers, overhead doors, dock lights, dock fans and Rite-Vu™ Hazard Recognition and Control. The Dok-Commander is compatible with most competitive hydraulic levelers.

- Application for Tight Door Centerlines – Dok-Commander combined controls allows for application of tight door centerlines by reducing the amount of loading dock controls into one simple, centralized control panel. Dok-Commander is narrower, allowing for tighter application, when compared to traditional loading dock configurations.

- Reduce Processes on Drive Approach – When equipped with Lok-Vu™, a single or dual camera outside view is displayed on the interior Dok-Commander® panel. The system helps to confirm when a trailer is present and properly secured as well as verify trailer stand presence, eliminating the need for workers to step outside on the dangerous drive approach.

- Dok-Lok® Status for Forklifts Entering and Exiting Trailer – System actively communicates Dok-Lok® status to material handlers entering and exiting the trailer via communication controls mounted to the left of the dock door opening.

- Withstand Harsh Loading Dock Environment – NEMA 4X Dok-Commander Combined Controls offer a superior level of protection from corrosion and extreme loading environments, such as: windblown dust and rain, splashing water, and more. The flexible circuitry meets changing needs with easily updatable components and add-on features. Exterior lights are UL listed and designed with energy saving LED bulbs.

- Reduce Human Error with Safe Sequence of Operations – Programmable to provide safe, custom sequential operation to help optimize safety at the loading dock or sequences to best fit your application: Door Protection Policy, Open Door Policy or Closed Door (Supply Chain Integrity) Policy. Safe Sequence of Operation helps ensure equipment is properly operated to protect employees, equipment and products by reducing human error and equipment faults.

- Industry-Recommended Electrical Best Practice – External disconnect (supplied by others) disconnects the electrical power supply from both the Dok-Commander® and the equipment for easy maintenance and service. The controls deliver broad compliance with national and local electrical codes.

- Help Minimize Risk when Maintaining Hydraulic Dock Levelers – Optional maintenance pendant receptacle helps minimize danger and reduce waste while promoting productivity when maintaining hydraulic dock levelers. The receptacle helps with labor shortages by only requiring one technician instead of two during maintenance.

- Physically Enhance Building Security – Dok-Lok® vehicle restraints help physically enhance security when the control package is linked with an active building security system. If an engaged restraint is tampered with, the building security system is notified and facility protocol is followed.

- Help Prevent Forklift Accidents at the Dock – With over 7,000 annual forklift accidents involving a forklift running off the edge of the dock, Light Communication Systems actively communicate restraint status to material handlers before they enter and exit trailers.

- Help Prevent Trailer Separation Accidents – Light Communication Systems help prevent trailer early departure by clearly informing dock personnel when they can safely enter or exit a trailer and inform truck drivers when it’s safe to depart.

- Line-of-Sight Light Communication – Compatible with the Dok-Commander, Corner-Vu™ and Leveler-Vu™ provide immediate line-of-sight Dok-Lok® status to material handlers entering and exiting the trailer, helping reduce unnecessary forklift traffic and miscommunication by clearly indicating green (safe to enter) and red (unsafe to enter). The enhanced visual communication system mitigates the risk of control box obstruction from pallets, personnel, and forklifts

Dok-Commander® offers enhanced communication between dock personnel inside the building and truck drivers outside of the building with inside controls, outside communication lights and interior/exterior instructional signs. The controls facilitate the ability to immediately or incrementally incorporate any Rite-Vu™ Hazard Recognition and Control component, allowing facilities to:

- Incorporate line of sight light communication system status with Corner-Vu™ and Leveler-Vu™

- Extend Blue Light Policy to help prevent 80,000 annual forklift-pedestrian accidents by extending reaction time with Pedestrian-Vu™

- Help prevent 2nd leading cause of backover fatalities in the United States with Approach-Vu™, which utilizes a light and horn system to present a clear visual and audible warning to pedestrians in the drive approach when a backing vehicle is detected.

- Verify Dok-Lok engagement and trailer stand presence via outside camera and inside monitor with Lok-Vu™, reducing the amount of processes on the dangerous drive approach.

All components are available as standalone or incorporated with Dok-Commander Combined Controls, which offers more flexibility, facilitating the greatest long-term yield per dock position. The systems allow facilities to address their most urgent safety needs first but reserving the opportunity to integrate vehicle restraints and other safety solutions at a fraction of the cost compared to standalone equipment purchases.

Want more visibility into dock performance for safety and productivity?

Connecting to the Rite-Hite ONE-enabled* Digital Platform provides real-time visibility and data to empower maintenance decisions, reduce inefficiencies and help mitigate safety events.

- Safety. Real-time alerts delivered to any device to identify and stop unsafe behavior, such as:

- Dok-Lok overrides and/or fault modes.

- Employee entering an unrestrained trailer.

- Dock door open but safety barrier not deployed.

- Productivity. Analytics gathered during each step of the loading process to identify bottlenecks and optimize operations, such as:

- Total duration of loading, to help avoid detention costs.

- Equipment utilization to determine under- or -over-usage.

- Trailer at dock but restraint not yet engaged.

- Uptime. Visibility into connected equipment status and service history, such as:

- Designate equipment state (out of service or immediate repair service required).

- Equipment performance trending down (cycle counts, use, service history).

- Document and log maintenance and services events.

* Rite-Hite ONE subscription required.

- 12-Month Limited Money-Back Guarantee of Customer Satisfaction

- Standard Warranty includes 1 year parts / 1 year labor

- Rite-Hite® Extended Warranty includes up to 5 year parts / 5 year labor and connected capabilities

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.