Rite-Hite ONE Control Tower

Rite-Hite ONE Digital Platform

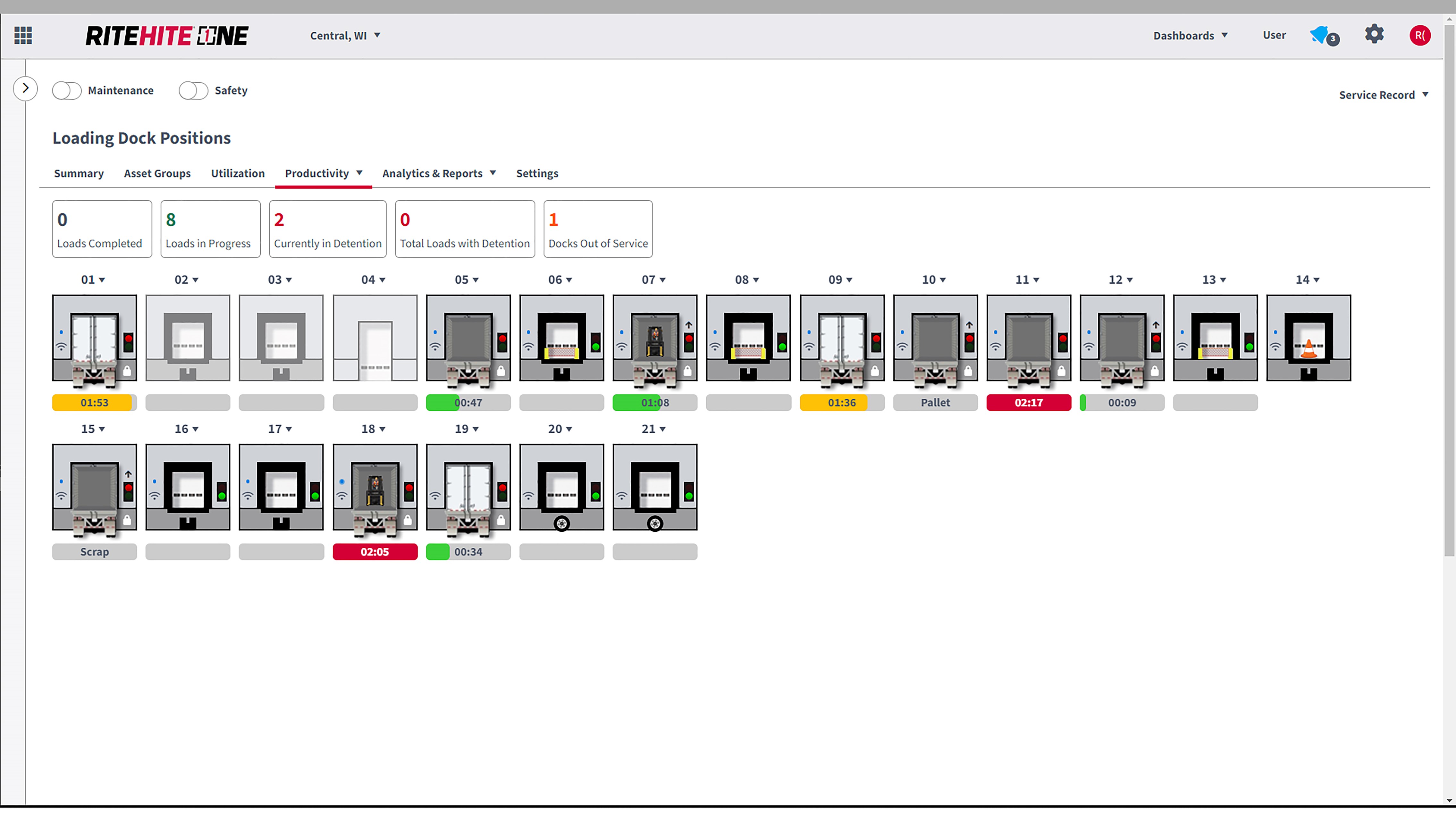

Are inefficiencies in your loading dock operations, such as extended trailer dwell times and unsafe working conditions, leading to increased detention charges and hindered throughput?

Loading dock productivity analytics can help improve staffing, scheduling, and overall dock efficiency and productivity. For example, when a trailer is sitting at a dock for a long period of time, the impact is felt in the subsequent processes. It can also lead to an overflow of goods in the staging area. In addition, loading docks are filled with potential danger, so proper safety procedures must be in place.

Gain meaningful insights to help reduce detention charges while maximizing

loading dock throughput.

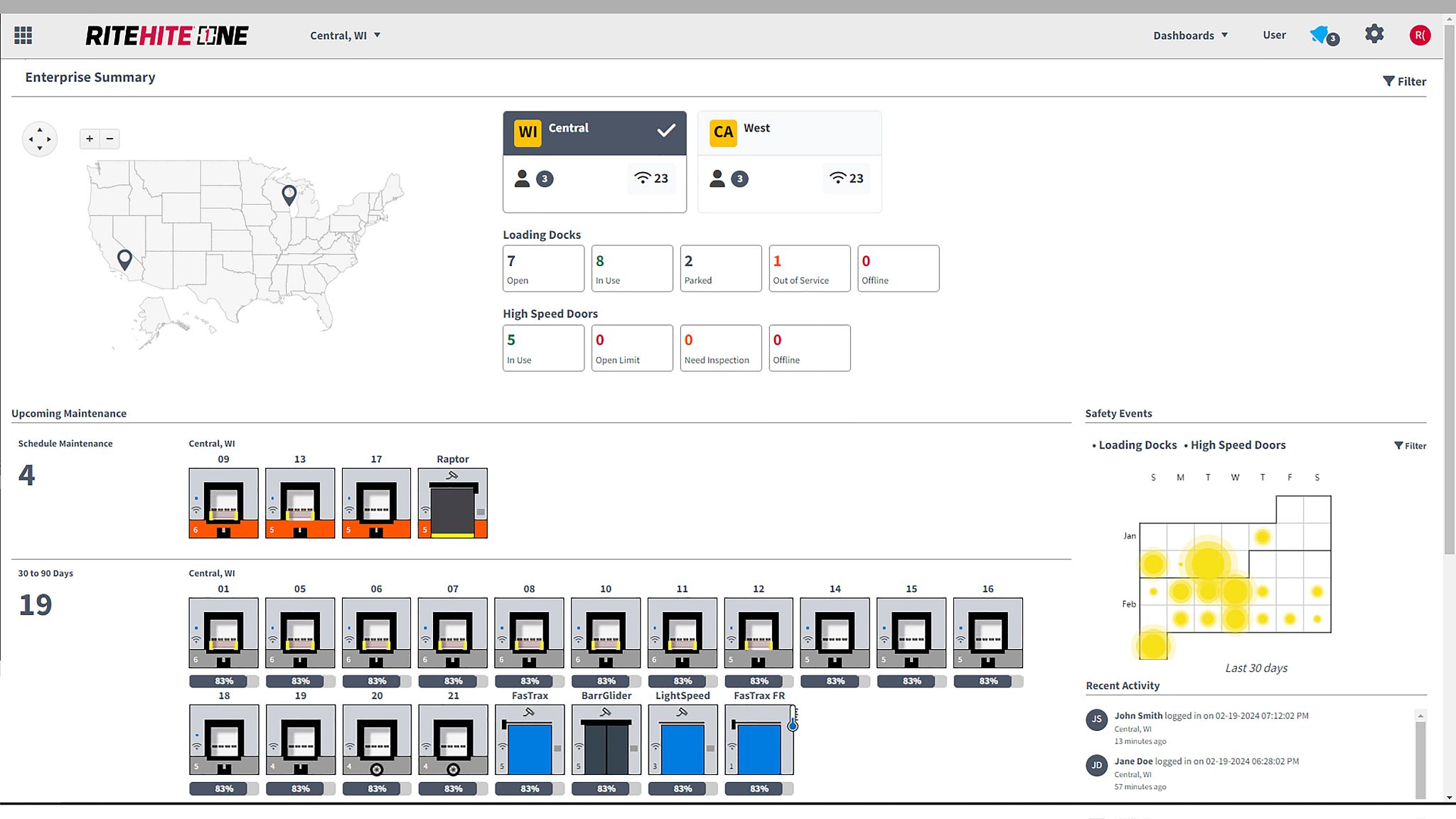

- Enterprise-Level Visibility: Obtain real-time views of loading dock activity. Whether you manage one facility or hundreds, take advantage of our enterprise

capabilities to manage operations across the nation. - Analytics: Maximize throughput using productivity analytics with current and historical utilization data.

- Tracking: Record average dwell time, detention metrics, and actual position utilization.

- Trending Alerts: Receive trending productivity alerts and review corrective actions/next steps.

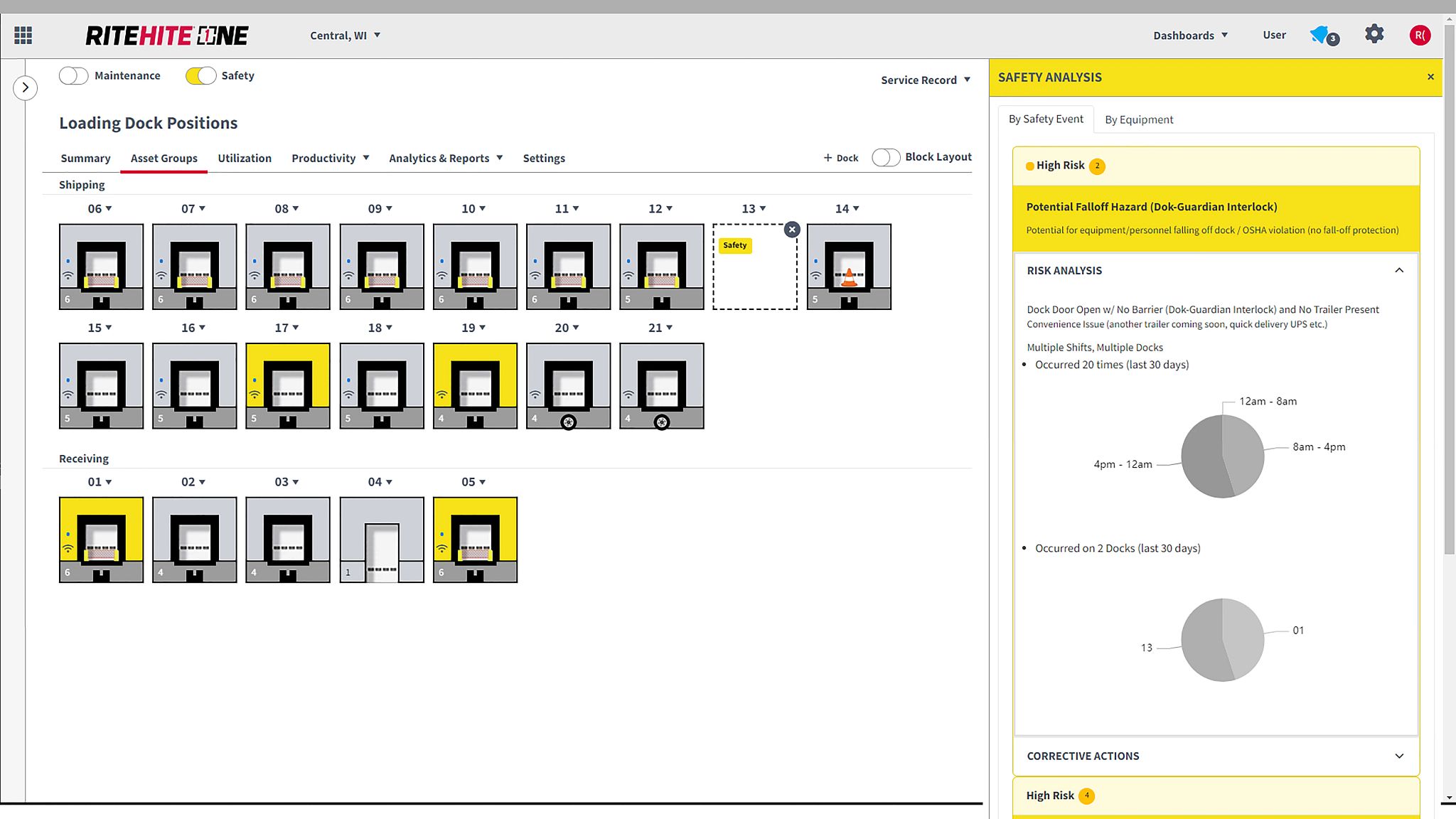

Are you dealing with near misses or unsafe events at your facility?

Facility safety and efficiency go hand-in-hand. Rite-Hite's safety data and analytics dashboard allows professionals to place a higher priority on specific safety events and improve warehouse safety best practices.

Leverage leading indicators and real-time notifications to ensure the safest, most

energy efficient equipment operation, driving down risk.

- Safety: Utilize safety cards to understand incidents at the loading dock and high speed doors.

- Alerts: Receive trending or real-time notifications based on incident type.

- Loading Dock: Dok-Lok® overrides, door open with restraint not engaged, and similar unsafe loading practices.

- High Speed Doors: Excess opens, false activations, curtain breakaways, etc.

- Analysis: Report by shift, position, or facility to drive safety target achievement.

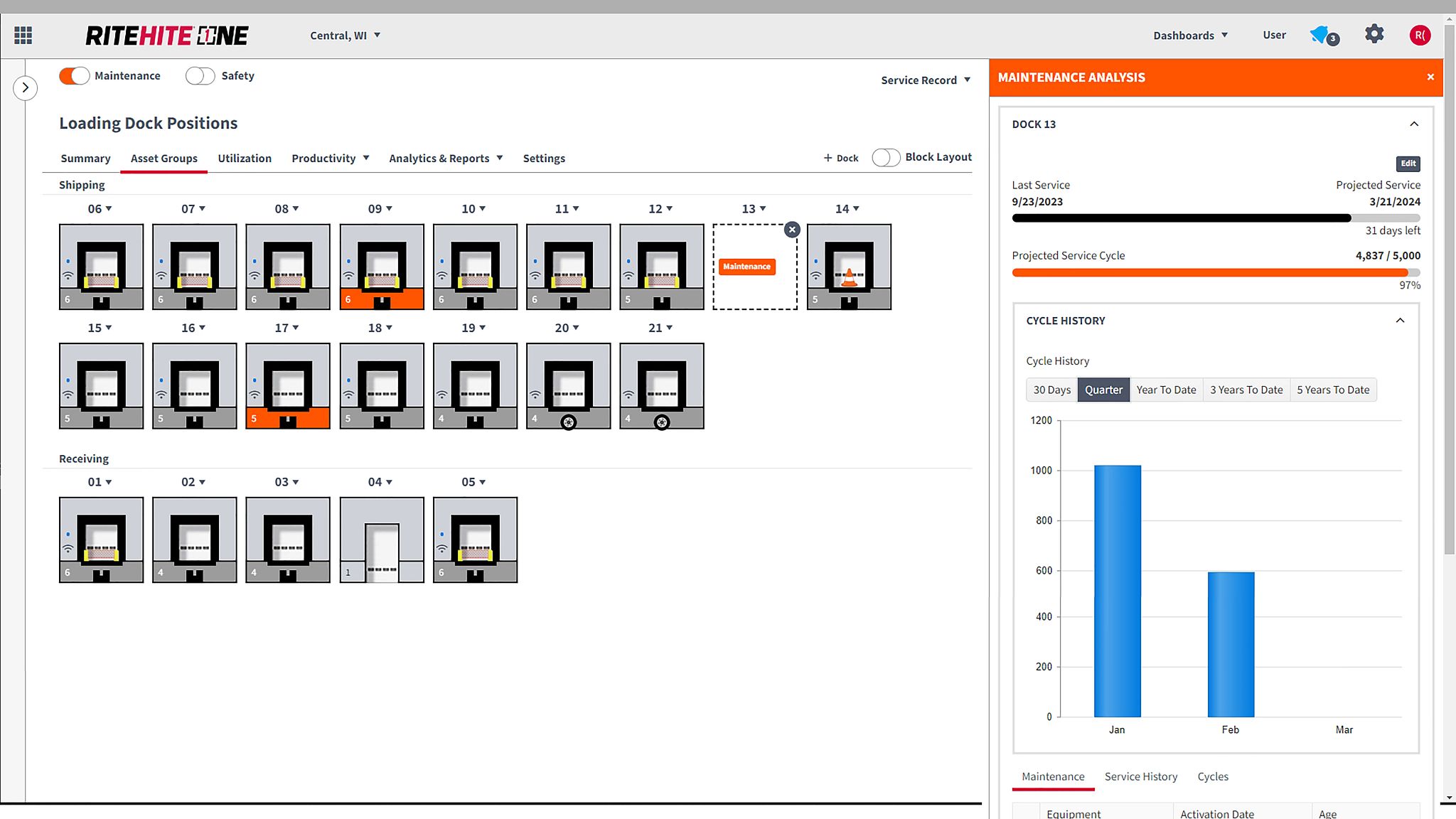

Are you struggling to maintain consistent operation due to unexpected equipment failures and inefficiencies in tracking maintenance schedules, leading to costly downtime?

Drive maximum uptime with simplified maintenance. Plan and track your downtime with confidence and monitor your asset cycle counts, receive notifications for overdue maintenance, ensuring timely attention to upkeep for optimal performance and longevity.

Become more proactive and ensure maximum uptime by gaining clarity into

equipment utilization and usage cycles.

- Log service history by asset for corrective or preventative actions.

- Track maintenance schedule by cycles or utilization.

- View upcoming service dates by dock position.

- Remotely set dock to “Out of Service” status.

What can smart, connected loading dock equipment do for you?

With Rite-Hite's smart, connected equipment powered by the Rite-Hite ONE digital platform, unforeseen issues and unpleasant surprises are eliminated. By providing real-time insights and predictive capabilities, smoother operations are assured, with fewer disruptions and increased performance across the facility. Simply put, the digital platform sets facilities up for a future where unexpected events no longer derail progress, but are anticipated and managed effectively.

What can we connect?

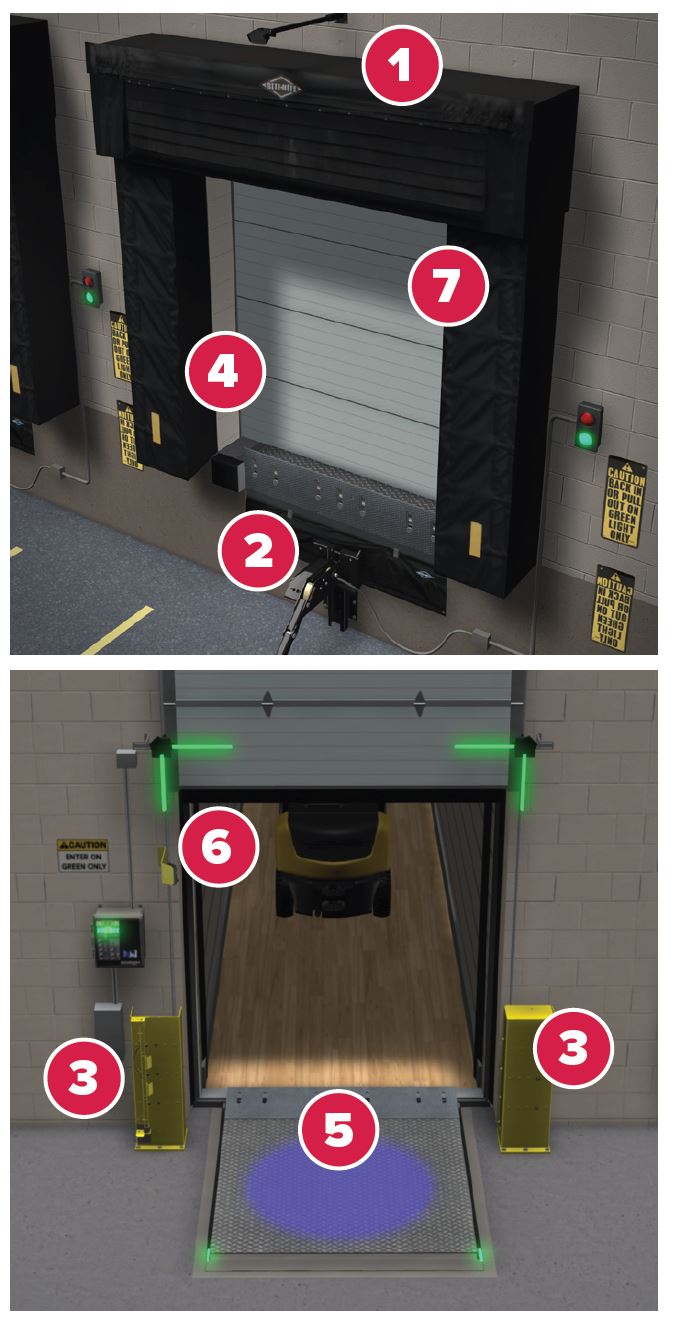

Connected Loading Dock Equipment

- Trailer Presence

- Vehicle Restraint Engagement

- Dok-Guardian® Interlock

- Door Open

- Leveler Stored

- Activity Inside the Trailer

- Door Close

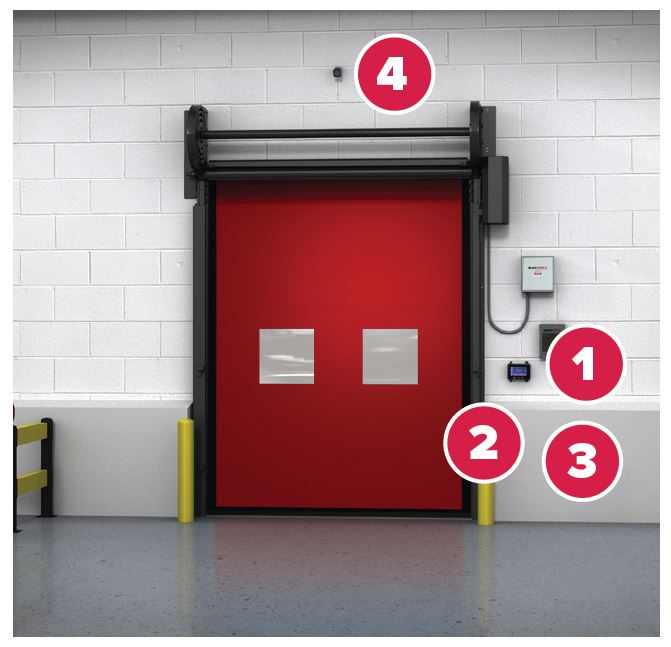

Connected Door Equipment

- False Activation

- Excessive Door Open

- Door Breakaways

- Falcon Motion Sensor

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.