Corner-Vu™ and Leveler-Vu™ Line of Sight Light Communication

Clearly inform dock personnel when they can safely enter and exit the trailer

Line-of-sight light communication status mitigates control box obstructions

Energy-saving low voltage LED lights

Benefits

Designed and Installed for Productivity

Safety at the Loading Dock

Communication and Control

Connected Capabilities

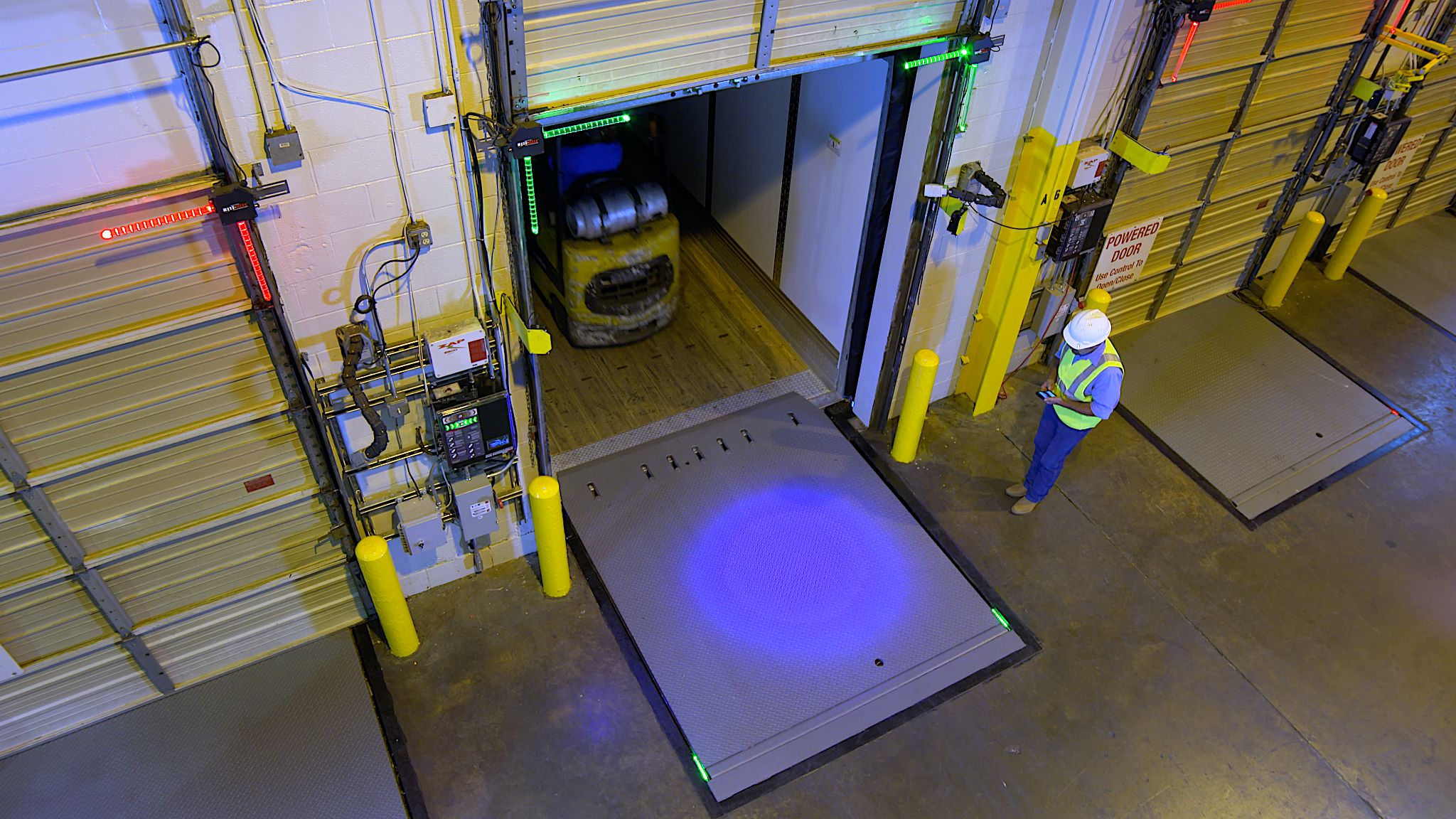

- Dok-Lok® Status for Forklifts Entering – Corner-Vu™ provides immediate line-of-sight Dok-Lok® vehicle restraint status to materials handlers entering the trailer via two auxiliary LED light brackets. Mounted to the upper corners of the interior loading dock doors, the enhanced visual communication system mitigates the risk of control box obstruction from pallets, personnel, and forklifts.

- Dok-Lok® Status for Forklift Exiting – Leveler-Vu™ provides immediate line-of-sight Dok-Lok® vehicle restraint status to materials handlers exiting the trailer, helping reduce unnecessary forklift traffic and miscommunication by clearly indicating green (safe to enter) and red (unsafe to enter). Mounted to each side of the leveler at the rear of the pit, the enhanced visual communication system mitigates the risk of control box obstruction from pallets, personnel, and forklifts.

- Virtual Filament Technology – Low voltage light emitting fixtures are designed to help reduce light pollution and allow for directional light.

- Dok-Lok® Style Light Communication System – Offers enhanced communication between dock personnel inside the building and truck drivers outside of the building. The NEMA 4X rated user interface with membrane switch buttons system allows for full integration of additional and future loading dock equipment, such as Corner-Vu™ and Leveler-Vu™. When interlocked in a safe sequence of operations, the controls help to ensure safety protocols and processes are followed.

- Withstand Harsh Loading Dock Environment – Leveler-Vu™ is installed below surface of stored leveler for non-direct contact with forklifts passing over loading dock leveler. Light brackets are fully epoxy sealed to perform in damp environments.

- Help Prevent Forklift Accidents at the Dock – With over 7,000 annual forklift accidents involving a forklift running off the edge of dock, Corner-Vu™ and Leveler-Vu™ actively communicate restraint status to material handlers before they enter and exit trailer.

- Help Prevent Trailer Separation Accidents – Line of sight light communication helps prevent trailer early departure by clearly informing dock personnel when they can safely enter or exit a trailer and inform truck drivers when it’s safe to depart.

Corner-Vu™ and Leveler-Vu™ are compatible with Rite-Hite restraint controls which offer enhanced communication between dock personnel inside the building and truck drivers outside of the building:

- Dok-Lok® Style Light Communication System –The NEMA 4X rated user interface with membrane switch buttons system allows for full integration of additional and future loading dock equipment. When interlocked in a safe sequence of operations, the controls help to ensure safety protocols and processes are followed.

- Dok-Commander® Combined Controls – Simple centralized panel integrates the controls of multiple pieces of loading dock equipment, including: Dok-Lok® vehicle restraint, dock leveler, dock door, dock light and Rite-Vu™ Hazard Recognition and Control systems. The NEMA 4x rated user interface with membrane switch buttons is programmable to provide safe, sequential operation to help optimize safety at the loading dock.

Want more visibility into dock performance for safety and productivity?

Connecting to the Rite-Hite ONE-enabled* Digital Platform provides real-time visibility and data to empower maintenance decisions, reduce inefficiencies and help mitigate safety events.

- Safety. Real-time alerts delivered to any device to identify and stop unsafe behavior, such as:

- Overrides and/or fault modes.

- Employee entering an unrestrained trailer.

- Dock door open but safety barrier not deployed.

- Productivity. Analytics gathered during each step of the loading process to identify bottlenecks and optimize operations, such as:

- Total duration of loading, to help avoid detention costs.

- Equipment utilization to determine under- or -over-usage.

- Trailer at dock but restraint not yet engaged.

- Uptime. Visibility into connected equipment status and service history, such as:

- Designate equipment state (out of service or immediate repair service required).

- Equipment performance trending down (cycle counts, use, service history).

- Document and log maintenance and services events.

* Rite-Hite ONE subscription required.

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.