GRH-100 Rotating Hook Restraint

Benefits

Overview

Safety at the Loading Dock

Designed and Installed for Productivity

Communication and Control

Connected Capabilities

Application

How well does your vehicle restraint address trailer separation accidents?

Rotating hook restraints help prevent all traditional trailer separation accidents, including: early departure, trailer creep, landing gear collapse, trailer pop-up and updending.

If your wheel chocks or current vehicle restraint's hook design isn't meeting your dock's needs, the GRH-100 Dok-Lok rotating hook restraint is the safest choice for an entry-level, powered rotating hook restraint.

- Rite-Hite's original "rotating hook" design brought a new level of safety to loading docks, creating the vehicle restraint industry in 1980.

- OSHA formally recognized the Dok-Lok as an alternative means to its wheel chocks standard (29 CFR 1910.78) in 1981.

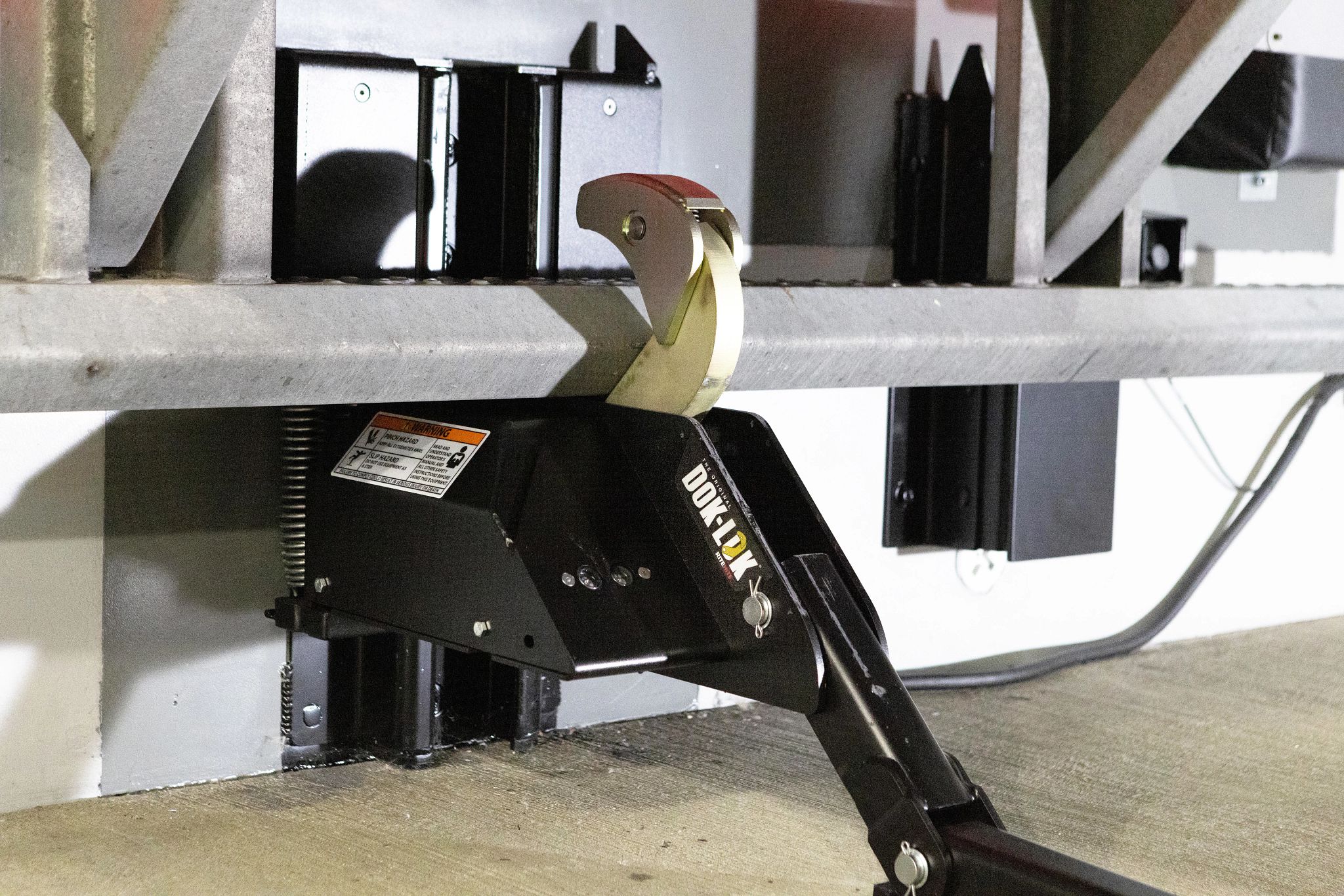

- GRH-100 is designed with an exclusive third-generation rotating hook that provides the most wrap in the industry, capturing traditional RIG-based trailers to help prevent trailer separation accidents..

- Backed by Rite-Hite's 12-Month Limited Money-Back Guarantee of Customer Satisfaction. Standard Warranty includes 1-year parts / 1-year labor. Rite-Hite Extended Warranty includes 2-year parts /2 -year labor and connected capabilities.

Is your restraint designed and built with a focus on loading dock safety?

The material handling industry reports more than 100,000 annual forklift accidents. Proper RIG engagement paired with constant restraint status communication helps prevent certain trailer separation accidents, including:

- Trailer creep

- Early departure

- Landing gear collapse

- Trailer pop-up

All Dok-Lok vehicle restraints come standard with red and green lights to communicate to drivers when it’s safe to back in or depart, and to dock workers when it’s safe to perform loading or unloading operations. Your vehicle restraints should also feature or support future integration of solutions that address trending pedestrian hazards that often occur outside on the dangerous drive approach and inside the loading dock.

Additional Dock Safety Products

Supporting solutions:

- Interlock Controls

- Rite-Vu™ Hazard Recognition and Control

- Dok-Commander® Combined Controls

- Wheel Guides

- Trailer Stands (necessary for dropped trailers)

Automation

Services:

Are you getting the full value from your vehicle restraint?

Product Specifications:

- Exclusive Contoured Hook Design

- Exclusive third-generation machined steel hook with silver zinc plating secures traditional RIG-based trailers to the loading dock by engaging outdated ICC bars, traditional 4x4 RIGs and pentagonal RIGs.

- Reliable Performance

- 9"-24" working range for consistent RIG and ICC bar contact.

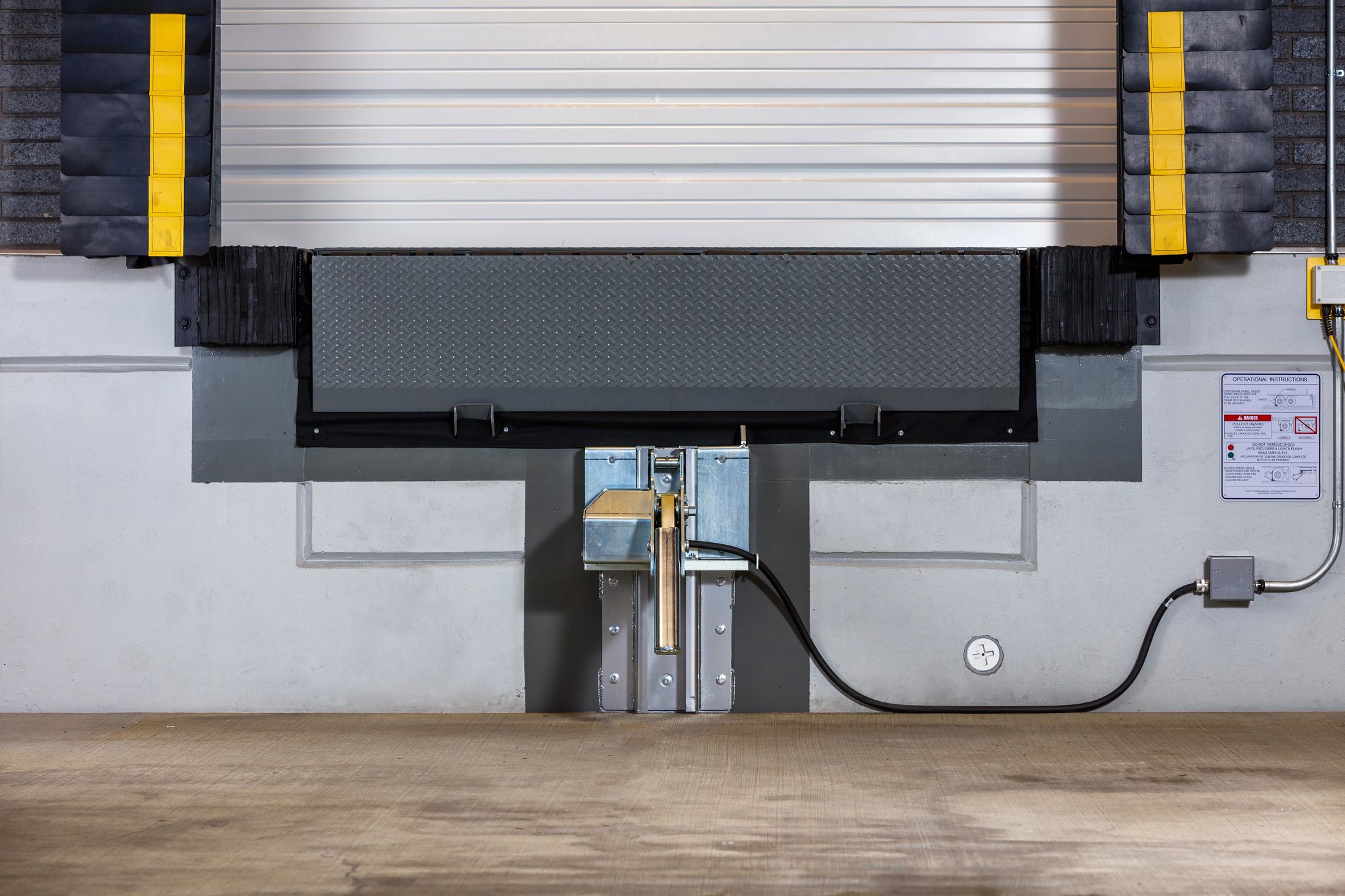

- Spring-loaded structural hardened steel housing with single clad track automatically positions when a backing trailer contacts the unit. The restraint is mounted above ground away from dirt, debris, snow, ice and standing water.

- Full complement needle bearing carriage rollers minimize damage from heavy loads and premature pullout attempts.

- 1/4 HP IP-66 motor provides dust- and water-infiltration protection

- Non-adjustable motor clutch, individually set at the factory, helps ensure that safety is never compromised in the field because a setting is "out of adjustment."

- All Dok-Lok vehicle restraints are certified to meet and exceed ANSI MH30.3 performance testing standards.

- Integrity of Installation

- The enclosed, 5/16" (8mm) welded steel is designed and installed with (15) 5/8" wedge style anchor bolts and 22" of weld to front curb angle to receive the impact of trailers backing into position.

- Completed dock survey required for each dock position to help ensure safe and proper application of all Dok-Loks®.

- Rite-Hite Standard Warranty includes 1-year parts / 1-year labor.

- Extended Warranty includes 2-year parts / 2-year labor.

- All Dok-Lok vehicle restraints are certified to meet and exceed ANSI MH30.3 performance testing standards.

- Pull-Out Force Benchmarks

- Rite-Hite was the first loading dock equipment manufacturer to establish pull-out force benchmarks based on years of research and development.

- All Rite-Hite restraints are installed with more than 100,000 lbs. of mounting force and 32,000 lbs. of pull-out force — double what tractors can achieve in first gear.

How clear is your communication at the loading dock?

Rite-Hite's communication systems enhance Dok-Lok safety by clearly informing dock personnel when they can safely enter or exit a trailer - and truck drivers when they can depart after loading or unloading.

Operated from a NEMA 4X interior panel, the GRH-100's standard Dok-Lok controls and Dok-Commander Combined Controls can interlock into a safe sequence of operations to help protect people, products and equipment by reducing human error and equipment faults.

-

Corner-Vu™

- Two auxiliary LED light brackets mounted to upper corners on interior loading dock doors provide immediate line-of-sight vehicle restraint status to material handlers entering trailer.

- Mitigates risk of control box sight obstruction from pallets, personnel and forklifts.

- Leveler-Vu™

- Two auxiliary LED lights mounted alongside the loading dock leveler pit, provides immediate line-of-sight for Dok-Lok vehicle restraint status to material handlers exiting trailer.

- Reduces unnecessary forklift traffic and miscommunication.

- Pedestrian-Vu™

- Addresses forklift-pedestrian accidents, which account for 80% of all reported forklift accidents by extending the forklift's blue light.

- Detects activity inside trailer with mounted sensors and emits intense blue light onto the leveler when motion is detected, communicating that dock personnel should proceed with caution.

- Can be interlocked with any Dok-Lok to help prevent disengagement for added safety and sounds alarm if unrestrained trailer is entered.

- Approach-Vu™

- Visual and audible warning system activated by presence of backing vehicle in the drive approach, indicating need for pedestrians to safely vacate due to potential threat.

- Available as standalone for facilities with simple wheel chocks or competitive units or embedded in VBR-350 housing.

- Lok-Vu™

- Lock verification system that utilizes an outside camera and inside monitor to show dock personnel when trailer arrives and is safely engaged or disengaged, reducing number of processes out on the dangerous drive approach.

- Dual camera option allows dock personnel to also confirm trailer stand presence in the case of spotted (dropped) trailers.

- Dok-Lok® Dock Timer

- Real-time display of active or total (un) loading duration for each dock position, helping improve loading efficiency by increasing capacity and trailer throughput.

- Integrate with trailer presence sensor to track duration from trailer arrival to Dok-Lok engagement via Rite-Hite ONE while also helping to keep boots off the ground to verify trailer arrival.

Want more visibility into dock performance for safety and productivity?

Dok-Lok Vehicle Restraints are Rite-Hite ONE-enabled. Connecting to this single Digital Platform provides real-time visibility and data to empower maintenance decisions, reduce inefficiencies and help mitigate safety events.

- Safety. Real-time alerts delivered to any device to identify and stop unsafe behavior, such as:

- Dok-Lok overrides and/or fault modes.

- Employee entering an unrestrained trailer.

- Dock door open but safety barrier not deployed.

- Productivity. Analytics gathered during each step of the loading process to identify bottlenecks and optimize operations, such as:

- Total duration of loading, to help avoid detention costs.

- Equipment utilization to determine under- or -over-usage.

- Trailer at dock but restraint not yet engaged.

- Uptime. Visibility into connected equipment status and service history, such as:

- Designate equipment state (out of service or immediate repair service required).

- Equipment performance trending down (cycle counts, use, service history).

- Document and log maintenance and services events.

* Rite-Hite ONE subscription required.

What challenges do you face at your loading dock?

The GRH-100 is the safest entry-level rotating hook restraint with minimal ability to upgrade but comes standard with the following features:

Trailer types

- Third-generation contoured hook to help securing traditional RIG types, including outdated ICC bars, 4x4 and pentagonal RIGs.

Dock environment

- Off-ground, mounted carriage for ease of snow removal.

- Full complement needle bearing carriage rollers to minimize damage from heavy loads and premature pullout attempts.

Loading style

- Rotating hook with widest wrap, helping address vertical separation accidents during dropped loading.

- Rotating hook with widest wrap and standard vehicle restraint status communication, helping address horizontal separation accidents during live loading.

Labor and operations

- NEMA 4X control panel for powered (automatic) operation.

- Interlock capable controls for ease of training to mitigate high employee turnover.

- Interior mounted controls operated with the push of a button to Dok-Lok restraint and enhanced with optional trailer presence sensor and Lok-Vu to support boots-off-the-ground out on the dangerous drive approach.

Related Products

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.